Cellulose insulation is a smart solution for reducing energy costs and improving home comfort. Made from 80–85% recycled paper, it forms a dense barrier that minimizes heat transfer and blocks air leaks. This eco-friendly material can save homeowners an average of 15% on heating and cooling costs, with even higher savings in colder climates. Its ability to fill small gaps and irregular spaces makes it particularly effective for attics, walls, and older homes.

Key benefits include:

- Energy Savings: Cuts heating and cooling costs by 15–20%.

- High R-Value: Offers 3.2–4.0 per inch, outperforming fiberglass.

- Noise Reduction: Reduces outside noise by up to 60%.

- Fire Resistance: Treated with borates for safety.

- Tax Credits: Claim 30% of material costs, up to $1,200 annually.

Cellulose insulation is especially useful in damp regions like the Pacific Northwest, thanks to its moisture-regulating properties. With proper installation, it can also extend HVAC lifespan and improve overall energy efficiency. Combine it with air sealing for the best results.

Cellulose Insulation: 5 Reasons To Use It In Your Attic

sbb-itb-8db64ac

What Is Cellulose Insulation and How Does It Work?

Cellulose insulation, crafted from recycled paper products, is an eco-friendly way to improve your home’s energy efficiency. It’s primarily made from materials like post-consumer newsprint, cardboard, and other wood-based fibers, with up to 85% of its content coming from recycled sources. To put that into perspective, insulating a 1,500-square-foot home can repurpose nearly 40 years’ worth of newspapers.

To ensure safety and durability, cellulose insulation is treated with borates (or boric acid), which make up about 15%–20% of its weight. This treatment makes the material fire-resistant, deters pests, and inhibits mold growth. Despite being paper-based, cellulose achieves a Class 1 fire rating. Instead of igniting, it chars, which slows the spread of flames.

The insulation works by forming a dense barrier that limits heat transfer through conduction and traps air to reduce heat flow. Its wood fibers naturally resist heat conduction, enhancing its thermal performance. As Paul Fisette, a former faculty member at the University of Massachusetts Amherst, explains:

Cellulose is made from wood fiber and the cellular structure of wood is naturally more resistant to the conduction of heat.

Cellulose insulation comes in two main forms. Loose-fill cellulose is blown into open spaces, like attics, where it settles and molds to fit irregular shapes. Dense-pack cellulose, by contrast, is installed under high pressure into enclosed wall cavities. This method fills even the smallest gaps, creating an airtight thermal barrier that minimizes heat loss and air leakage. The way it’s installed directly impacts its R-value and overall performance.

Understanding R-Value in Cellulose Insulation

R-value is a measurement of how well insulation resists heat flow – the higher the number, the better the performance. For cellulose insulation, the R-value ranges from 3.2 to 3.8 per inch. When dense-packed into wall cavities, it can achieve up to R-4.0 per inch.

| Insulation Material | R-Value per Inch | Recycled Content |

|---|---|---|

| Loose-fill Cellulose | 3.2 – 3.7 | Up to 85% |

| Dense-pack Cellulose | 3.8 – 4.0 | Up to 85% |

| Fiberglass (Batt) | 3.0 – 3.2 | 20% – 30% |

| Loose-fill Fiberglass | 2.2 – 2.7 | 20% – 30% |

Unlike fiberglass, which relies on trapped air to insulate, cellulose’s dense fibers physically block air movement. This ensures consistent thermal performance, even in conditions where air leakage might otherwise reduce effectiveness. Dense-pack cellulose is particularly effective for wall retrofits, as it completely fills cavities and prevents settling or gaps over time.

Environmental Benefits of Cellulose Insulation

Cellulose insulation isn’t just energy-efficient – it’s also environmentally friendly. Producing cellulose requires about eight times less energy than fiberglass (when comparing energy costs per installed R-value unit), reducing both embodied energy and carbon emissions during manufacturing.

It also serves as a carbon sink. As the Cellulose Insulation Manufacturers Association (CIMA) explains:

Cellulose insulation is basically plant cell matter in the form of paper that is made from wood and thus contains high percentages of carbon. When added to homes… cellulose insulation traps that carbon for years effectively lowering the carbon footprint of homes.

Instead of decomposing in a landfill and releasing carbon dioxide, the recycled paper remains locked in your home for decades.

Another benefit is cellulose’s hygroscopic nature – it can absorb and release moisture, moving it from areas of high concentration to low concentration. This helps prevent moisture buildup in walls, which is especially useful in damp regions like the Pacific Northwest. Plus, its high density provides excellent soundproofing, absorbing 80% or more of sound, with a Noise Reduction Coefficient of 0.80 or higher.

How Cellulose Insulation Reduces Energy Consumption

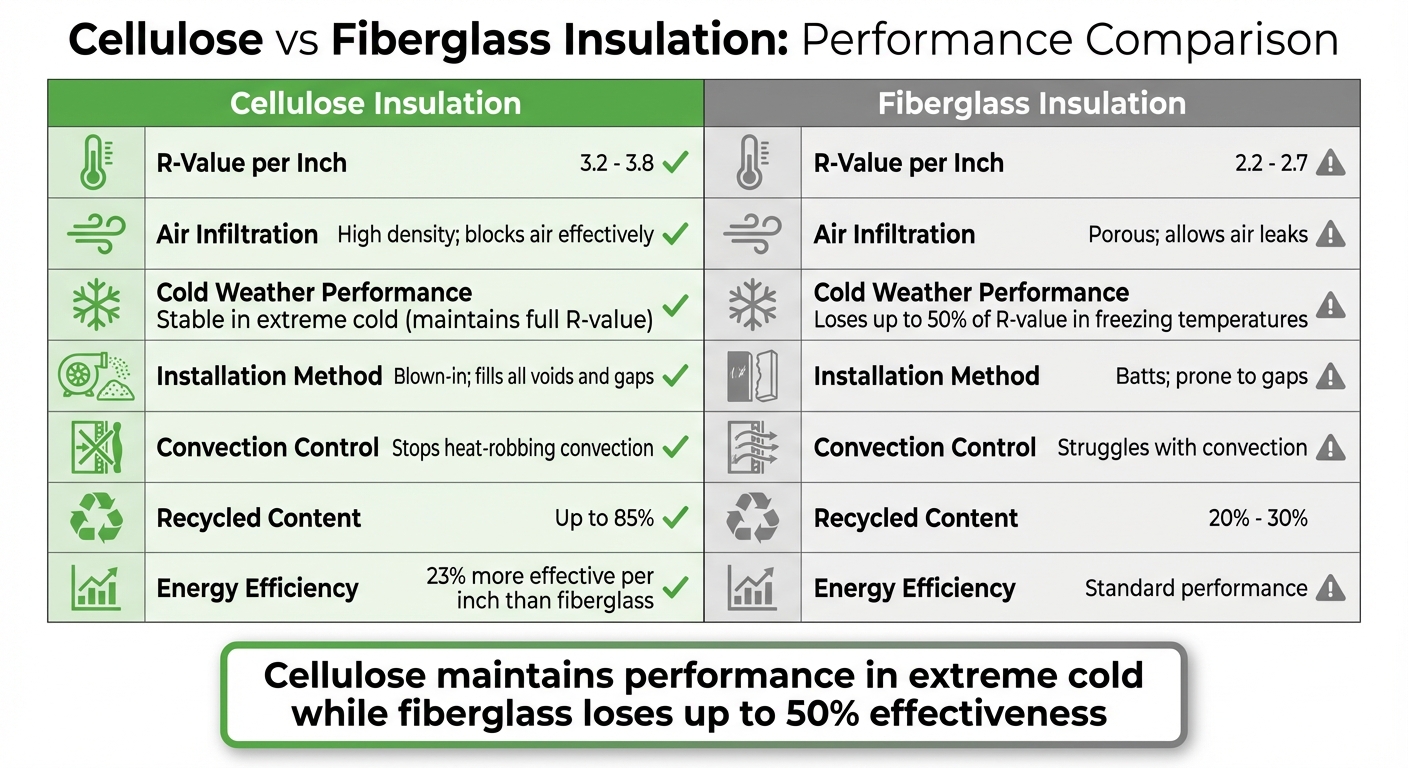

Cellulose vs Fiberglass Insulation: Energy Efficiency Comparison

Cellulose insulation isn’t just eco-friendly and fire-resistant – it’s also a powerhouse when it comes to improving energy efficiency. It achieves this through two main mechanisms: sealing air leaks and providing excellent thermal performance. When installed correctly, cellulose forms a dense barrier that keeps heat indoors during winter and blocks it out in the summer. According to Energy.gov, combining air sealing with added insulation in attics and floors can save homeowners an average of 15% on heating and cooling costs (or 11% of total energy expenses).

The material curbs heat flow in three ways: through the gaps between fibers, the wood fibers themselves, and the air pockets trapped within. Together, these elements create a steady thermal barrier that eliminates temperature fluctuations across rooms and levels, easing the demand on HVAC systems.

Air Sealing Benefits

One standout feature of cellulose insulation is its ability to block air movement, something traditional batt insulation often struggles with. When blown into spaces, cellulose fibers pack tightly into cracks, gaps, and tiny crevices that other materials might miss. This dense application creates a physical barrier against air leaks caused by wind, the stack effect, or pressure imbalances inside your home.

Marc Tannenbaum from Dr. Energy Saver highlights this:

Compared to fiberglass, cellulose is a superb air-blocker.

The material’s density plays a critical role here. The Cellulose Insulation Manufacturers Association (CIMA) elaborates:

The higher the density of the material, the better it is at inhibiting the movement of air. Both cellulose and closed-cell foam insulations have a much higher density than fiberglass.

The U.S. Department of Energy also notes:

The addition of dense-packed cellulose to wall cavities can provide significant air-sealing benefits.

For the best results, combine cellulose insulation with targeted air sealing around plumbing, electrical outlets, and window frames. While its air-blocking properties are impressive, cellulose’s real strength lies in maintaining reliable thermal performance – even under extreme conditions.

Thermal Performance Compared to Fiberglass Insulation

Beyond its air-sealing capabilities, cellulose insulation stands out for its thermal performance. With an R-value of 3.5 to 3.8 per inch, cellulose is about 23% more effective per inch than fiberglass batts. But the difference becomes even more evident in extreme cold. While fiberglass can lose as much as 50% of its R-value in freezing temperatures, cellulose maintains its insulating power.

| Feature | Cellulose Insulation | Fiberglass Insulation |

|---|---|---|

| R-Value (per inch) | 3.2 – 3.8 | 2.2 – 2.7 |

| Air Infiltration | High density; blocks air | Porous; allows air leaks |

| Cold Weather Performance | Stable in extreme cold | Loses up to 50% of R-value |

| Installation Method | Blown-in; fills voids | Batts; prone to gaps |

| Convection Control | Stops heat-robbing convection | Struggles with convection |

Cellulose’s edge over fiberglass stems from its wood fiber structure. Unlike fiberglass, which is made from glass, cellulose’s natural fibers are better at resisting heat conduction. This means cellulose doesn’t just trap air but actively reduces heat transfer through its fibers, ensuring consistent energy efficiency throughout your home.

Financial Benefits of Cellulose Insulation

Investing in cellulose insulation can lead to significant financial advantages, both immediately and over time. While the initial cost might seem high, the savings on utility bills and the potential increase in your home’s value make it a worthwhile expense. Heating and cooling typically account for about 43% of a home’s energy costs, so improving insulation can lead to noticeable savings. For example, homes in colder regions like Climate Zone 7 can cut heating and cooling costs by as much as 19%, while even homes in warmer areas, such as Climate Zone 1, can see savings of around 7%. If your household spends $2,000 annually on heating and cooling, a 15% reduction translates to $300 saved each year. These savings not only lower your yearly expenses but also make a difference in your monthly utility bills.

Reducing Monthly Utility Bills

Cellulose insulation offers ongoing financial relief by reducing energy costs. With U.S. electricity prices increasing nearly 40% since 2004, energy efficiency improvements are more valuable than ever. As the North American Insulation Manufacturers Association explains:

Insulating is one of the most cost effective ways to stop overspending on your energy bill.

Currently, around 90% of U.S. homes are under-insulated, meaning many homeowners are losing money each month without realizing it. A quick inspection of your attic can reveal whether you need more insulation – if your attic floor joists are visible, it’s a clear sign you may need an upgrade. Beyond saving on monthly bills, there are also programs that can help reduce the cost of installation.

Available Rebates and Incentives

Federal, state, and local programs provide financial support to offset the upfront costs of installing cellulose insulation. Through the Energy Efficient Home Improvement Credit (Section 25C), homeowners can claim 30% of their material costs as a federal tax credit, up to $1,200 annually. This credit has no lifetime cap, meaning you can claim it every year you make qualifying improvements through 2025.

For low- and moderate-income households, the High-Efficiency Electric Home Rebate Act (HEEHRA) offers even more support. Low-income homeowners (earning less than 80% of the area median income) can have 100% of project costs covered, up to $1,600. Moderate-income households (earning between 80% and 150% of the area median income) can receive 50% of project costs, also up to $1,600. Unlike the federal tax credit, HEEHRA rebates include both material and labor costs.

Local utility companies also offer additional incentives. For instance, the Energy Trust of Oregon provides rebates ranging from $0.75 to $2.25 per square foot, depending on the type of insulation and the homeowner’s income status. One homeowner, Cherrie Carlson-Conklin from Baker City, shared her experience:

Our new attic and wall insulation is making a significant difference in our energy bills. Our house is warmer, cozier and not as drafty in winter.

Companies like Envirosmart Solution specialize in helping homeowners navigate these programs to maximize their savings. Their team stays informed on federal, state, and local rebate opportunities, ensuring you take full advantage of all available incentives. By combining multiple programs, they can help offset most – if not all – of your installation costs, turning your insulation upgrade into a smart financial decision.

Envirosmart Solution: Your Partner in Energy Efficiency

![]()

Proper installation is key to getting the most out of your insulation. When done professionally, it ensures effective air sealing and full coverage, leading to significant long-term energy savings. Envirosmart Solution provides homeowners across the Pacific Northwest with insulation services designed to boost both comfort and energy efficiency.

Professional Installation Services

The performance of cellulose insulation largely depends on the quality of its installation. Professional installers use targeted inspections to identify and address critical areas, ensuring maximum effectiveness. This is important because air leaks alone can cause between 25% and 40% of a home’s energy loss. By sealing gaps around windows, doors, and plumbing penetrations before adding insulation, homeowners can reduce overall energy loss by as much as 20%.

Envirosmart Solution takes a comprehensive approach, offering detailed air sealing to close gaps, cracks, and irregular spaces, creating a more efficient thermal envelope. Their team also handles the removal of outdated insulation when needed. With their precise inspections and sealing techniques, they not only improve insulation performance but also help homeowners qualify for available rebates. They ensure your cellulose insulation meets regional R-value standards, such as R-60 for attics and R-30 for floors in areas like Seattle.

But insulation is just one piece of the puzzle – an integrated approach can take your home’s energy efficiency to the next level.

Complete Home Solutions

Envirosmart Solution goes beyond insulation to offer services that enhance indoor air quality, comfort, and energy efficiency. Their comprehensive offerings include HVAC maintenance, moisture control, and air quality improvements, creating a home environment where all systems work together seamlessly.

This holistic approach addresses moisture control and ventilation services alongside insulation. By tackling issues like mold growth and structural damage, they protect your home while maximizing energy savings. Whether you’re looking for a single upgrade or a full home energy makeover, their all-in-one service model simplifies the process and ensures every system operates efficiently.

Conclusion

Cellulose insulation stands out as a practical choice for homeowners, offering notable energy savings, cost efficiency, and reduced environmental impact. This recycled material not only provides excellent thermal performance but also helps homeowners cut heating and cooling expenses by an average of 15%. Considering that heating and cooling typically make up about 43% of a household’s utility bill, these savings can make a noticeable difference.

When installed properly using the dense-pack method, cellulose insulation reduces air leaks, lowers utility costs, and even extends the lifespan of HVAC systems. However, its effectiveness hinges on precise installation – achieving the correct density, sealing air leaks thoroughly, and addressing potential risks like roof leaks or outdated wiring. As highlighted by the U.S. Department of Energy:

The performance of insulation is very dependent on the quality of the installation; contractors that are familiar with the products you are considering will increase the likelihood that they will be installed properly.

Envirosmart Solution ensures homeowners get the full range of benefits from cellulose insulation. Their expert team takes a comprehensive approach, addressing insulation, attic and crawl space cleaning, air sealing, moisture control, and HVAC efficiency. They also help property owners tap into rebates and incentives, including federal tax credits that cover up to 30% of material costs.

Choosing cellulose insulation with professional installation is a smart, long-term decision. It leads to lower energy bills, improved comfort, and a reduced environmental footprint – making it a win-win for both homeowners and the planet.

FAQs

Is cellulose insulation safe in a house?

Cellulose insulation is considered safe when installed correctly. It’s treated with fire-retardant chemicals to minimize fire risks, as well as to prevent mold and mildew growth. Regulatory agencies also classify it as non-toxic. However, if the material isn’t treated properly, it could become a fire hazard, and pests might disrupt the insulation. Opting for professional installation can help mitigate these risks and ensure long-term safety.

Will cellulose insulation settle over time?

When cellulose insulation is used in attics, it tends to settle over time, usually by about 13–20% until it reaches a stable density. However, in sidewalls, proper installation prevents settling, ensuring the insulation remains effective at maintaining energy efficiency and performance.

Do I qualify for insulation tax credits or rebates?

If you’re considering installing insulation, you might be eligible for tax credits or rebates – but only if you act by December 31, 2025. For qualifying insulation, such as cellulose, the federal tax credit covers 30% of product costs, with a maximum credit of $1,200. This applies to purchases made between January 1, 2023, and December 31, 2025. Be sure to review the specific eligibility criteria to confirm your insulation meets the requirements.

Related Blog Posts

- Attic Insulation R-Value Calculator

- Insulation Cost Estimator

- Best Insulation Types for Pacific Northwest Homes

- 5 Ways Poor Insulation Increases Energy Bills