Choosing between spray foam and fiberglass insulation depends on your priorities: cost, energy efficiency, and moisture control. Spray foam offers better performance but comes at a higher upfront cost, while fiberglass is budget-friendly and easier to install. Here’s a quick breakdown:

- Spray Foam: Higher R-value (3.5–7 per inch), excellent air sealing, long lifespan (50–100 years), and moisture resistance. Costs $1,500–$6,000 for installation. Ideal for damp climates or areas needing airtight seals.

- Fiberglass: Lower R-value (2.2–4.3 per inch), affordable ($150–$750 for a 500 sq. ft. area), easier DIY option, but less effective at air sealing and prone to moisture issues. Lifespan is 10–20 years.

- Spray Foam vs Fiberglass: Which Insulation is Best for YOUR Home?

- Spray Foam Insulation: How It Performs

- Fiberglass Insulation: How It Performs

- Spray Foam vs Fiberglass: Side-by-Side Comparison

- How to Choose the Right Insulation for Your Home

- Which Insulation Type Should You Choose?

- FAQs

- Related Blog Posts

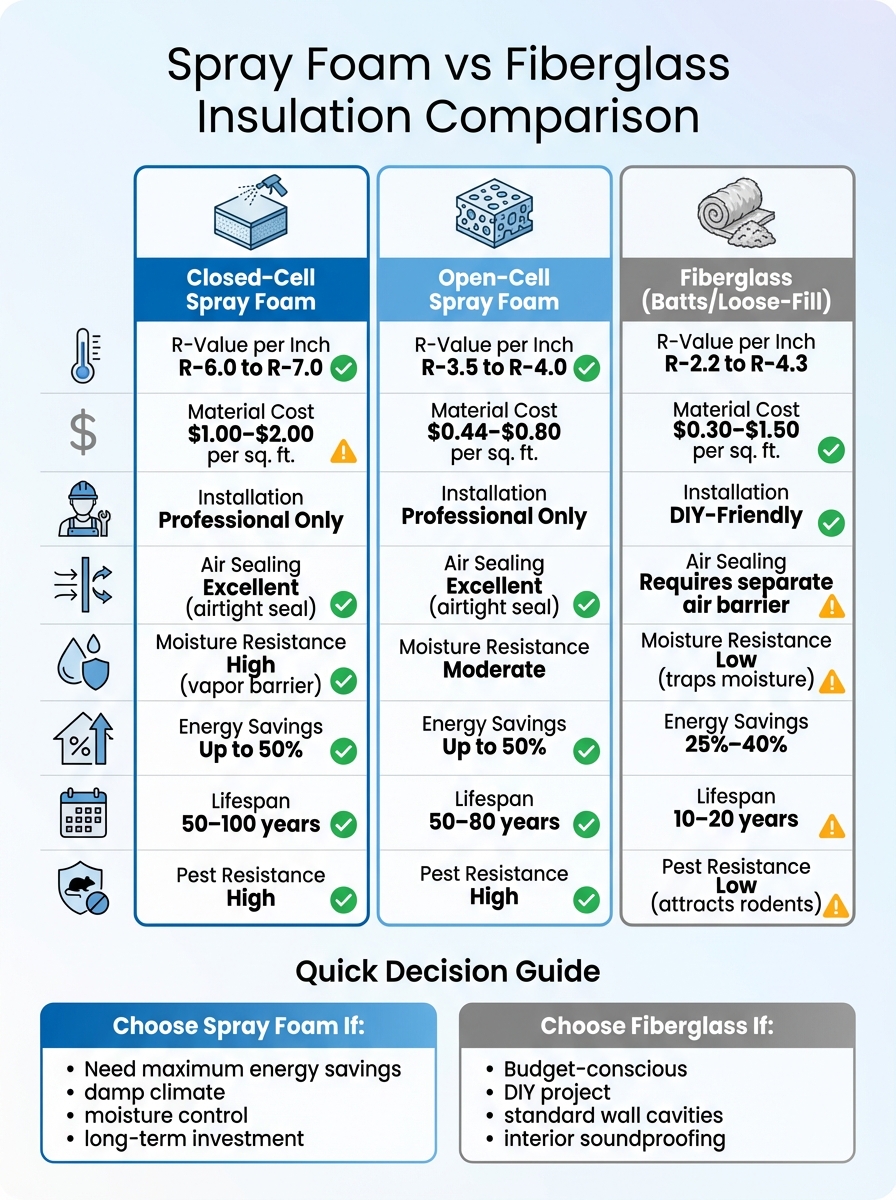

Quick Comparison

| Factor | Spray Foam (Closed-Cell) | Spray Foam (Open-Cell) | Fiberglass (Batts/Loose-Fill) |

|---|---|---|---|

| R-Value per Inch | 6.0–7.0 | 3.5–4.0 | 2.2–4.3 |

| Cost | $1.00–$2.00/sq. ft. | $0.44–$0.80/sq. ft. | $0.30–$1.50/sq. ft. |

| Air Sealing | Excellent | Excellent | Requires extra air barrier |

| Moisture Resistance | High | Moderate | Low |

| Lifespan | 50–100 years | 50–80 years | 10–20 years |

| DIY-Friendly | No | No | Yes |

If you’re in a damp climate or want maximum energy savings, spray foam is worth the investment. For budget-conscious projects, fiberglass is a solid choice but may require additional air sealing for optimal performance.

Spray Foam vs Fiberglass Insulation Comparison Chart

Spray Foam vs Fiberglass: Which Insulation is Best for YOUR Home?

Spray Foam Insulation: How It Performs

Spray foam insulation is a standout option for reducing energy loss, thanks to its ability to expand 30 to 60 times its original liquid volume. This expansion creates an airtight seal, effectively blocking air leaks that contribute significantly to energy waste in homes. But not all spray foam is created equal – there are two main types, each with distinct characteristics and advantages.

Open-Cell vs. Closed-Cell Spray Foam

Open-cell spray foam is lightweight and soft, with a porous structure that offers an R-value of R-3.5 to R-4.0 per inch. Weighing about 0.5 pounds per cubic foot, it’s particularly effective at soundproofing, making it an excellent choice for interior walls. However, its permeability to moisture means it needs extra protection in damp environments.

Closed-cell spray foam, on the other hand, is dense and rigid, weighing around 2.0 pounds per cubic foot. It delivers a higher R-value of R-6.0 to R-7.0 per inch. This type of foam is water-resistant and acts as a vapor barrier when applied at a thickness of approximately 1.5 inches. In areas like the Pacific Northwest, where damp conditions are common, closed-cell foam is often the go-to option for basements, crawl spaces, and exterior applications to prevent moisture-related issues.

Joseph Lstiburek from Building Science Corporation highlights the versatility of spray foam:

"Spray foam is unique in that it has the ability to handle all four [water, air, vapor, and heat] although many designs do not require spray foam to handle all four."

Benefits of Spray Foam Insulation

One of the standout benefits of spray foam insulation is its ability to create a seamless air barrier. Unlike fiberglass, which can leave gaps, spray foam forms a continuous seal that can reduce heating or cooling energy loss by up to 30%. This translates to significant savings, with homeowners often cutting energy bills by 30% to 50% annually.

Spray foam also stands the test of time. It doesn’t sag, settle, or shrink, maintaining its R-value for the lifetime of a home – estimated at 80 to 100 years. Closed-cell foam provides additional benefits, such as reinforcing wall strength and improving indoor air quality by reducing the infiltration of allergens like dust and pollen. Its resistance to moisture also makes it mold-resistant, a feature especially valuable for homes in damp climates like the Pacific Northwest. In unvented attics, closed-cell spray foam can prevent roof deck condensation, offering further protection.

Drawbacks of Spray Foam

Despite its many advantages, spray foam insulation comes with some downsides. Cost is a significant factor. Open-cell spray foam costs between $0.25 and $2.50 per board foot, while closed-cell options range from $0.75 to $4.50 per board foot. For an entire home, installation costs typically fall between $1,500 and $6,000, with an average of around $2,885.

Installation isn’t a DIY project. The process involves mixing isocyanates and polyol resins, which release fumes that require vacating the home for 24 to 48 hours. Once installed, spray foam is difficult to remove or modify, which can complicate access to wiring or plumbing later on. Improper installation could also trap moisture, potentially hiding issues like roof leaks until they cause significant damage. Additionally, some lenders may be hesitant to finance homes with spray foam due to the potential costs of removal.

While the upfront expense is higher, many homeowners find the investment pays off within 2 to 4 years through energy savings.

Fiberglass Insulation: How It Performs

Fiberglass insulation is found in 90% of North American homes, thanks to its affordability and efficiency. Made from glass fibers – 40% to 60% of which are recycled – it works by trapping air within its fibers to slow heat transfer. When paired with proper moisture control, it’s a reliable option, especially in regions like the Pacific Northwest.

This insulation comes in two main forms, each suited to specific applications. Batts are pre-cut, flexible blankets designed to fit standard stud spacing of 16 or 24 inches. These are best suited for new construction or remodels with open wall cavities. Loose-fill insulation, on the other hand, consists of small fibers blown into spaces using specialized equipment. It’s ideal for irregular areas, attic floors, or retrofitting existing walls with minimal disruption. While batts are a DIY-friendly option requiring basic tools, loose-fill often requires professional installation due to the equipment involved. Let’s compare these forms to understand how they address different insulation needs.

Batts vs. Loose-Fill Fiberglass

Choosing between batts and loose-fill largely depends on your project and the areas you’re insulating. Batts are great for walls, floors, and ceilings with standard framing, but they can leave gaps if not carefully trimmed around obstacles like wires or pipes. Loose-fill, in contrast, forms a seamless layer in attics and works well for retrofitting closed wall cavities without major demolition. However, loose-fill can settle over time, which may require periodic refilling. For example, achieving R-15 in a 10-square-foot wall with loose-fill costs between $3.40 and $4.00.

Benefits of Fiberglass Insulation

Fiberglass’s affordability is a major advantage. With costs ranging from $0.30 to $1.50 per square foot, it’s one of the most budget-friendly insulation materials. Insulating a 500-square-foot area typically costs between $150 and $750. When properly installed and combined with air sealing, fiberglass can cut heating and cooling costs by 40% to 50%, potentially reducing overall energy expenses by up to 40%.

Beyond cost savings, fiberglass offers other practical perks. It’s non-combustible and doesn’t require added fire-retardant chemicals. Around 90% of residential fiberglass insulation is formaldehyde-free. It also provides excellent soundproofing, with a Noise Reduction Coefficient (NRC) of 1.0 and a Sound Transmission Coefficient (STC) of 43. For DIY enthusiasts, batts are easy to install without needing specialized tools.

Drawbacks of Fiberglass Insulation

Despite its strengths, fiberglass insulation comes with some challenges. For starters, it doesn’t act as an air barrier. Without sealing air leaks, up to 30% of a home’s heating or cooling can escape through areas insulated with fiberglass alone. This makes additional measures, like caulking gaps and sealing cracks, essential for optimal performance.

Moisture is another concern. As Lee Wallender from The Spruce cautions:

"Fiberglass should never be used when moisture is even remotely present".

When fiberglass gets wet, it can clump, lose its insulating ability, and even encourage mold growth. This makes it unsuitable for damp spaces like basements or crawl spaces unless proper moisture barriers are in place.

Fiberglass performance can also decline over time. Alexis Dingeldein from South Central Services explains:

"Fiberglass insulation performance is likely to deteriorate after 15 to 20 years".

Gravity can cause batts to sag or fall, especially in floors or crawl spaces, creating gaps that weaken your home’s thermal barrier. Allison Bailes from Energy Vanguard puts it plainly:

"Gravity is patient. Even though it’s the weakest of the three fundamental forces of nature, it’s plenty strong enough to pull those batts down over time. And it’s relentless".

Proper installation is critical. Any rips, gaps, or compression during installation can reduce fiberglass’s R-value. Additionally, the material’s glass fibers can irritate the skin, eyes, and lungs, so wearing protective gear like gloves, respirators, and long sleeves is a must. Lastly, fiberglass can attract rodents, which may use it as nesting material.

sbb-itb-8db64ac

Spray Foam vs Fiberglass: Side-by-Side Comparison

Let’s break down how spray foam and fiberglass stack up when it comes to performance and cost.

Comparison Table: Performance and Cost

Here’s a closer look at how these insulation options compare:

| Factor | Closed-Cell Spray Foam | Open-Cell Spray Foam | Fiberglass (Batts/Loose-Fill) |

|---|---|---|---|

| R-Value per Inch | R-6.0 to R-7.0 | R-3.5 to R-3.6 | R-2.2 to R-4.3 |

| Material Cost | $1.00–$2.00 per sq. ft. | $0.44–$0.80 per sq. ft. | $0.30–$1.50 per sq. ft. |

| Installation | Professional Only | Professional Only | DIY-Friendly |

| Air Sealing | Creates airtight seal | Creates airtight seal | Requires separate air barrier |

| Moisture Resistance | High (Vapor Barrier) | Moderate (Air Barrier) | Low (Traps moisture) |

| Energy Savings | Up to 50% | Up to 50% | 25%–40% |

| Lifespan | 50–100 years | 50–80 years | 10–20 years (before sagging) |

| Pest Resistance | High | High | Low (attracts rodents) |

Yasir B from Sprayfoam Solutions Toronto highlights the air sealing advantage:

"Air leakage can contribute to 40 percent of a home’s energy loss. Spray foam solves this fairly easily by filling in the gaps and cracks."

Compared to fiberglass, spray foam reduces air permeability by 24 times. This means fiberglass requires an additional air barrier to be effective, whereas spray foam combines insulation and air sealing in one step.

The table outlines the key differences, but how do these factors translate into long-term savings?

Long-Term Return on Investment

While spray foam has a higher upfront cost – 2 to 3 times more than fiberglass – the long-term savings often justify the expense. Homeowners typically recoup their investment within 3 to 5 years through lower energy bills. Older homes with poor insulation can see energy savings of up to 30%, while newer homes might save 10% to 15%.

For example, insulating a 500-square-foot area with fiberglass costs between $150 and $750, whereas spray foam averages $2,500 to $2,885. However, fiberglass may need replacing after 15–20 years, while spray foam is a lifetime solution requiring little to no maintenance once installed.

Closed-cell spray foam also offers structural reinforcement, strengthening walls and roof decking – something fiberglass cannot do. With around 90% of single-family homes in the U.S. under-insulated, upgrading insulation can increase your home’s value by 2% to 6%.

How to Choose the Right Insulation for Your Home

Selecting insulation for your home involves balancing your budget, climate needs, and long-term plans. Let’s break it down by cost, climate considerations, and how insulation upgrades can tie into broader home improvements.

Initial Cost vs. Long-Term Savings

When it comes to cost, fiberglass insulation is one of the most affordable options, priced at around $0.30–$1.50 per square foot. Spray foam, on the other hand, ranges from $0.44–$0.65 per board foot for open-cell and $1.00–$1.50 per board foot for closed-cell varieties. While spray foam is initially more expensive, it can deliver energy savings that pay off over time. For older homes with poor insulation, spray foam can cut energy costs by as much as 30%. Newer homes may see savings between 10% and 15%.

There’s also a federal tax credit to consider. It covers 30% of material costs, up to $1,200, which can further improve the return on your investment. Fiberglass is a great choice for budget-conscious DIYers tackling standard wall cavities, while spray foam’s superior air-sealing properties make it ideal for tricky, moisture-prone spaces.

Performance in Pacific Northwest Climate

Your local climate plays a big role in insulation performance. In the Pacific Northwest, where damp conditions are common, closed-cell spray foam is an excellent choice. It acts as a watertight vapor barrier, reducing drafts and cutting heating and cooling costs by about 15%. Fiberglass, however, doesn’t hold up as well in wet conditions, as moisture can degrade its effectiveness.

In areas like attics, spray foam shines by preventing the sagging and settling that fiberglass often experiences in damp environments. Its ability to seal cracks and gaps also reduces drafts – an important factor since up to 40% of a building’s energy can escape through air leaks. If you choose fiberglass in a moisture-prone area, professional air sealing beforehand is essential, as fiberglass alone doesn’t effectively block air infiltration.

Combining Insulation with Other Home Services

Upgrading insulation can enhance your home’s overall efficiency, especially when paired with other improvements. For instance, spray foam sealing can reduce HVAC system sizing needs by up to 30%, leading to lower equipment costs and fewer repairs over time.

Before upgrading insulation, schedule an attic inspection to check for mold or moisture issues. Contaminated fiberglass insulation will need to be replaced. Services like Envirosmart Solution’s Crawl Space & Attic Care™ package ($199 annually) include inspections for insulation, air gaps, and rodents, plus a 15% discount on follow-up services. Pairing insulation upgrades with mold remediation, vapor barrier installation, and HVAC adjustments creates a more efficient and cohesive home system.

Which Insulation Type Should You Choose?

The choice between spray foam and fiberglass insulation depends on your priorities – whether it’s energy efficiency, moisture control, or sticking to a budget. Take into account your home’s specific needs to decide which option aligns best with your goals.

When to Choose Spray Foam

Spray foam is ideal when air sealing and moisture control are top priorities. This type of insulation works especially well in areas like crawl spaces, basements, and attics, particularly in regions like the Pacific Northwest where damp conditions can challenge traditional insulation methods. Closed-cell spray foam even doubles as a watertight vapor barrier, offering extra protection against moisture issues.

It’s also great for sealing tricky gaps around plumbing vents, wiring holes, and rim joists. Thanks to its ability to expand, spray foam effectively fills hard-to-reach spaces. While the upfront cost is higher, the energy savings – up to 30% in older homes – can make up for it in just three to five years. Plus, federal tax credits may cover 30% of material costs, up to $1,200, making it a more affordable long-term investment.

When to Choose Fiberglass

Fiberglass insulation is the go-to choice for those looking to keep initial costs low. It’s the most budget-friendly option and performs well in standard wall cavities, making it a solid pick when cost is a primary concern. It’s also a popular choice for DIY projects, as it doesn’t necessarily require professional installation.

Another advantage of fiberglass is its soundproofing ability, which makes it a great fit for interior walls in spaces like bedrooms, home offices, or media rooms. However, fiberglass doesn’t naturally block air leakage, so pairing it with additional air-sealing measures may be necessary to match the performance of spray foam.

Get Professional Help from Envirosmart Solution

![]()

Still unsure which insulation type is right for you? Envirosmart Solution can help by evaluating your home’s needs and recommending the best solution – whether that’s spray foam, fiberglass, or a hybrid "flash and batt" approach that blends both materials for cost-effective results.

Their Crawl Space & Attic Care™ package, priced at $199 annually, includes inspections for insulation quality, air gaps, and rodent damage. They also offer a 15% discount on follow-up services. By bundling insulation upgrades with services like vapor barrier installation, mold remediation, or HVAC adjustments, you can create a more efficient home system that reduces energy costs and keeps your living space comfortable all year long.

FAQs

What’s the difference between open-cell and closed-cell spray foam insulation?

Open-cell spray foam is a lightweight and flexible insulation option. With a lower R-value (a measure of thermal resistance), it’s particularly useful for soundproofing or areas where only minimal insulation is needed. Unlike closed-cell foam, it’s not a vapor barrier and allows some air to pass through, which can be advantageous in specific scenarios.

Closed-cell spray foam, by contrast, is much denser and more rigid. It boasts nearly double the R-value of open-cell foam, making it highly effective for insulation. It also serves as a vapor barrier and creates an airtight seal, which helps enhance energy efficiency and control moisture in your home. Though it comes with a higher price tag, its durability and superior insulating capabilities often make it a smart choice for those seeking long-term performance.

What are the long-term costs of spray foam insulation compared to fiberglass?

Spray foam insulation might come with a higher initial price tag compared to fiberglass, but its impressive R-value and ability to seal air leaks can result in noticeable energy savings over time. These savings often balance out the initial expense, offering a more economical option in the long run.

On the other hand, fiberglass insulation is generally less expensive upfront, but it usually falls short in terms of energy efficiency and durability. For homeowners aiming to lower energy bills and enhance overall comfort, spray foam insulation presents a practical long-term investment, even with its higher starting cost.

Is fiberglass insulation a good choice for damp climates like the Pacific Northwest?

Fiberglass insulation might not be the ideal choice for damp regions like the Pacific Northwest. Why? It has a tendency to absorb moisture. When this happens, its ability to insulate effectively drops, and over time, it can start to sag or even deteriorate.

In areas with high humidity or consistent rainfall, it’s crucial to look for insulation materials designed to resist moisture while staying effective. Picking the right insulation not only keeps your home comfortable but also helps maintain energy efficiency in the long run.

Related Blog Posts

- Winter Home Energy Efficiency Checklist

- Attic Insulation R-Value Calculator

- Insulation Cost Estimator

- 7 Signs Your Attic Insulation Needs Replacement